Knorr-Bremse Will Be Trialling Automated Brake Testing On A HVLE Train

posted on 20th Jul 2022 08:01

Working together with Havelländische Eisenbahn (HVLE), Knorr-Bremse is equipping a freight train with an automation system that will support automated brake testing. At the same time, Knorr-Bremse is producing the first prototypes of its own DAC. Both innovations are being systematically prepared for market launch as part of a package of rail freight solutions.

Knorr-Bremse’s FreightControl automation system comprises a new kind of electronics that combines centralised wagon intelligence with innovative sensor technology for the braking system. Because the train is not yet fitted with DACs, so does not have a train-wide data bus, the data signal for the brake testing system is transmitted wirelessly. The train will be retrofitted starting in 2023 and is due to go into service in 2024.

The trial promises to deliver valuable insights into the potential benefits of automated brake testing for rail freight in general. Today, the brakes on the 500,000 or so wagons in the EU are still manually tested by rail yard personnel – so brake testing is an exceptionally time-consuming step in the setup process. Once testing can be carried out from the driver’s cab using, for example, a handheld tablet, it will help ensure that freight trains are ready for departure significantly faster.

Knorr-Bremse will take advantage of this trial to further accelerate the development of its train automation system. As well as automated brake testing, this will include other functions such as train composition recognition, train integrity monitoring and an electropneumatic brake control system. Together with the DAC, this will result in a package of tightly interconnected solutions for digital freight trains.

And thanks to Knorr-Bremse’s active involvement in the Europe’s Joint Rail Undertaking (ERJU), the package will be interoperable, meaning fully compatible with all operators’ systems and fleets. Consequently, it will help dramatically improve the process efficiency and competitiveness of the rail industry as a whole.

Knorr-Bremse is also making major progress in developing the DAC (FreightLink), and has assembled the first prototypes at its main plant in Budapest. Top priorities include safety, durability and performance. Made of special steel, the coupling system can withstand the enormous torsional and longitudinal forces generated when freight trains are moving, braking or maneuvering.

At the same time, Knorr-Bremse has focused on optimising the DAC’s life cycle costs and ensuring that it can be maintained efficiently. The Knorr-Bremse DAC is an enabler in every sense – both of train automation functions and of digital services. Among other benefits, Knorr-Bremse’s proven aftermarket and digital expertise means that the company will be able to offer customers smart maintenance and ancillary services (including Condition-Based and Predictive Maintenance) that depend on big data analytics in the Cloud.

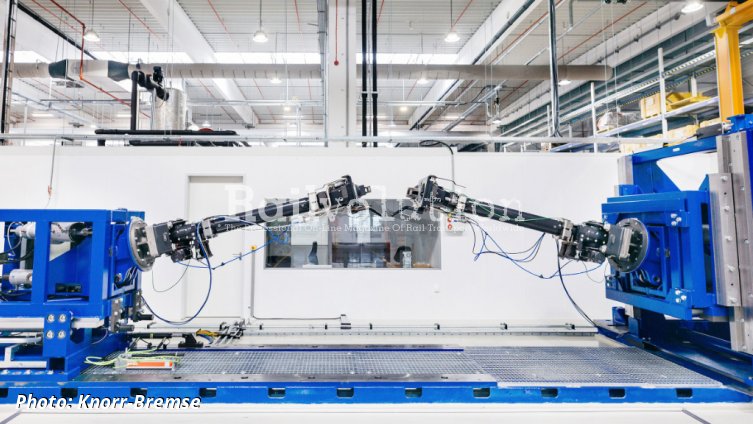

Knorr-Bremse will subject the latest DAC design – as well as the company’s new passenger train couplers – to extensive testing on its new, custom-built test rig in Budapest, focusing in particular on the coupling and uncoupling of rail vehicles. Later in the year, Knorr-Bremse is already planning to install a more advanced version of the DAC in a rake of wagons for testing under real operational conditions, as part of the ERJU.

By 2025, the aim is to develop – in collaboration with other ERJU partners – market-ready products for the anticipated DAC rollout. In parallel, Knorr-Bremse is working on its own electric contact coupler, which will also be brought to market as part of the ERJU.